Infrastructure

Introduction to Kopac Joint Stock Company’s Infrastructure and Production Lines

1. Factory Scale and System

Kopac Joint Stock Company owns a modern factory system with a total area of thousands of square meters, scientifically constructed and arranged to meet all standards of occupational safety, industrial hygiene, and environmental protection.

Main components include:

- Main production area: Operates advanced corrugated carton and carton box production lines, arranged in a closed process from raw materials to finished products.

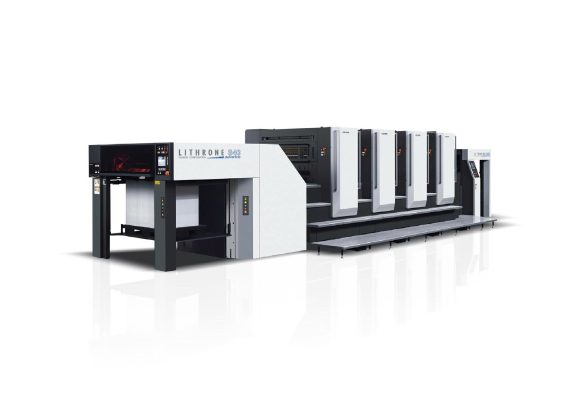

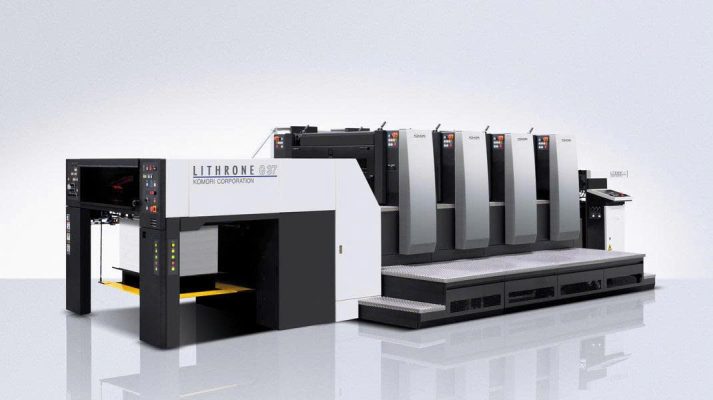

- Printing and processing area: Equipped with offset printers, flexo printers, die-cutting machines, automatic gluing and stapling machines, ensuring high accuracy and sharp print quality.

- Raw material warehouse: Large area with a strict storage management system, ensuring paper materials maintain the best quality before production.

- Finished goods warehouse: Spacious, well-ventilated, ensuring convenient and fast storage and shipping.

- Office area: Integrates production management, quality control, and customer service systems.

2. Machinery and Production Equipment

To enhance production capacity and meet large order volumes, Kopac invests in synchronized machinery systems, applying the most advanced technology in the carton packaging industry:

- Automatic corrugated board production line: Produces a variety of wave types (A, B, C, E, AB, AC, BC, BE) ensuring good compression strength and elasticity.

- Multi-color offset printer: Produces sharp, true-to-color images, suitable for high-end and export packaging.

- Flexo printer: High-speed printing over large areas, ideal for standard carton packaging.

- Die-cutting machine: Accurately processes designs according to customer specifications.

- Automatic gluing machine: Ensures solid adhesion, neat edges, and increased productivity.

- Industrial stapling and adhesive machines: Guarantees packaging durability during transportation.