Types of Cardboard Boxes

Cardboard boxes are currently designed with various structures, sizes, and shapes to maximize efficiency during transportation. So, what are the most popular types of cardboard boxes today? How can cardboard boxes be classified? KOPAC will help you answer these questions in detail, enabling you to choose the cardboard box model that suits your business needs.

How to Classify Cardboard Boxes

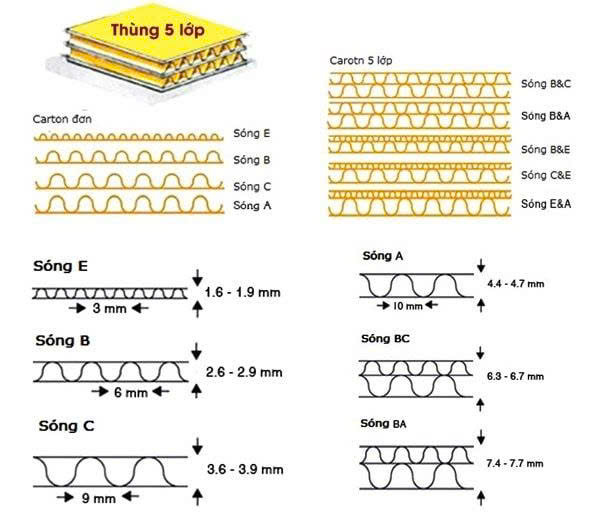

By Flute Height

Cardboard boxes are made from wood fibers, which then undergo a process of corrugation and bonding of paper layers to form the finished product. The corrugated paper structure of the cardboard box includes the following types:

| Flute Type | Height | Characteristics |

| A-Flute | 4.5 – 5.0mm | Provides good force distribution across the entire surface of the paper sheet. |

| B-Flute | 2.4 – 3.0mm | Offers high puncture resistance. |

| C-Flute | 3.5 – 4.2mm | Combines the advantages of A-flute and B-flute. |

| E-Flute | 1.2 – 2.0mm | Often used to produce cardboard boxes specialized for light objects. |

| AB-Flute | 7.0 – 7.7mm | A combination of one A-flute layer and one B-flute layer, providing optimal thickness and load-bearing capacity. |

| BC-Flute | 5.0 – 6.7mm | A combination of one B-flute layer and one C-flute layer, providing high thickness and load-bearing capacity. |

| ACB-Flute | 12.0mm | A combination of all three flute layers A, C, and B, providing the box with superior thickness and exceptional load-bearing capacity. |

By Number of Layers

Cardboard boxes typically consist of 3, 5, or 7 layers. You can distinguish the corresponding box type based on the number of structural layers.

- 3-layer cardboard box: The two outer faces of the box are made with a smooth, flat paper layer, with a sinusoidal corrugated paper layer in the middle. This type of box is affordable, with good compression strength and burst resistance. Therefore, businesses can use 3-layer cardboard boxes for light goods with no risk of damage to optimize costs.

- 5-layer cardboard box: Composed of 3 flat paper layers and 2 alternating corrugated layers. Typically, 5-layer cardboard boxes use AB and BC flutes to increase thickness and load-bearing capacity, suitable for fragile goods.

- 7-layer cardboard box: Composed of 4 flat paper layers and 3 alternating sinusoidal corrugated layers. This type of box has a thick and sturdy structure, suitable for packaging and shipping in the export and logistics fields.

By Structure

Depending on the structure, cardboard boxes are divided into many different types. The most common ones include: cardboard box with a lid, cardboard box without a lid, full-overlap cardboard box, die-cut cardboard box, etc. Each of these types of cardboard boxes offers a specific utility, meeting certain needs.

The Most Popular Types of Cardboard Boxes Today

Current cardboard box types are designed with various shapes, structures, and sizes to suit a wide range of products. Below are the 7 most popular types of cardboard boxes today.

Regular Slotted Container (RSC) Cardboard Box

The Regular Slotted Container (RSC) cardboard box is also called the A1 box. It consists of 2 ends with 4 flaps each. Before use, you need to ensure the bottom flaps are securely taped.

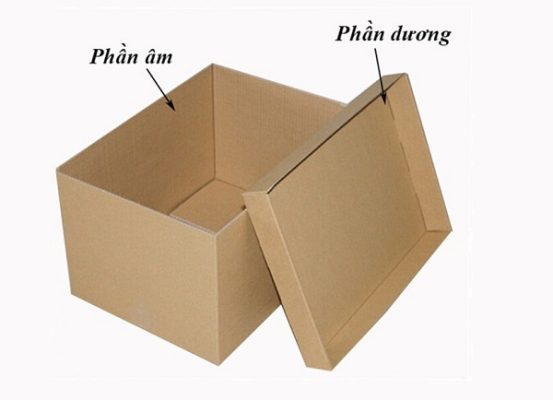

Telescope Cardboard Box (Lid and Base)

This is a type of cardboard box with a detached lid. The lid is usually 2 – 3mm wider to cover the outer part of the box sufficiently when packaged. The telescope cardboard box model is often specially designed according to the size, style, and load-bearing capacity of the product, thereby ensuring the best quality during packaging and transportation.

Full Overlap Slotted Container (FOL) Cardboard Box

The Full Overlap (FOL) cardboard box is similar in appearance to the RSC box (A1). The only difference is that its two main flaps overlap each other. This type of cardboard box is suitable for packaging large and heavy products that need surface protection. When stacking goods, it can withstand downward pressure and is extremely resistant to impacts.

Cardboard Box with Handle

This is one of the types of cardboard boxes designed separately with a lock-style bottom and a folding lid that serves as a convenient handle. Cardboard boxes with handles are often used for gifts, fast food, fruits, etc.

Tuck-Top Cardboard Box

The tuck-top cardboard box is designed with a single folding lid that covers the entire top of the box. The folding lid has two small side wings. The end of the lid has a small excess of about one centimeter so that when closed, it can be tucked into the pre-cut slot.

With a self-locking structure that does not require tape, the tuck-top cardboard box ensures aesthetics and sturdiness. Therefore, this type of box is always the choice for businesses trading in fashion, cosmetics, food, etc.

Cardboard Box with Tuck-Top and Interlocking Bottom

This type of paper box has a very special design. The bottom is designed with 4 folding flaps and interlocking tabs that can be securely folded together without the need for adhesive tape. The lid is designed in a folding style with two small wings on the sides.

The cardboard box with tuck-top and interlocking bottom is also one of the common cardboard box types today. This type of paper box is widely applied and found everywhere.

Cardboard Boxes Using Custom Die-Cuts

For products with special dimensions that do not fit regular cardboard box types, businesses can order custom die-cut cardboard boxes. With a special method and design, this type of box can preserve your product in the best way.

>>>See more:

Types of Cardboard Flutes